HOMEWORK

did a little research and consultation with alot of experienced people and some of the most significance one was from uncle Pungky (B.P. Kusumo Bintoro)... as usual, his resourcefulness has amazed me again ![]()

ok so now we start with M20B25

bore 84mm (with 0.2mm off due to heat, need to either bore it to bigger size or resleeve it back to 84mm, i rather bore it up)

stroke 75mm

Piston CH 34.7mm

conrod length: 135mm

now, i could just rebuild it back to normal, but i decided to do upgrade while at it to ease the pain ![]()

the weapon of choice is:

Crankshaft and Con Rod

from M52B28

stroke is 84mm

conrod length is the same with M20B25: 135mm

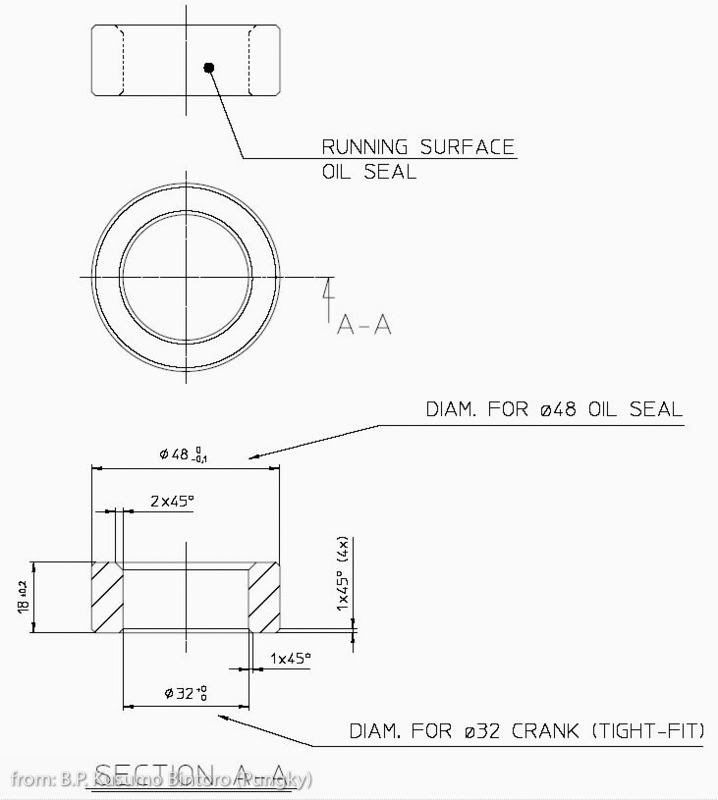

however some modification needed. see the comparison of both crank from M20B25 (left) and M52B28 (right), need to add the extra sleeve in order for the M52B28 crank to sit properly on M20B25 block

and uncle Pungky (B.P. Kusumo Bintoro) is kind enough to provide me with the CAD tech drawing of it for the machine shop

PISTON with the correct Compression Height (CH)

so now the correct piston CH that i need is: 34.7mm - (84-75)/2 = 30.2mm

the 2 closest candidate with bigger bore than 84mm is:

M43B19TU piston with CH 30.4mm Bore 85mm

or

M44B19 piston with CH 30.4mm Bore 85mm

but then my good friend Posma has supply me with M44B19 Oversize 85.5mm Piston, so the bore will be 85.5mm (will be confirmed tomorrow when i see him)

so the final displacement would be: 84 * * (85.5 / 2)*(85.5/2) * 6 = 2894cc

* (85.5 / 2)*(85.5/2) * 6 = 2894cc

and for the head gasket, uncle pungky suggested: E36 M3 S50B30 head gasket as it has 86mm bore, or custom made

that is all so far...

Thursday, December 16, 2010

HOMEWORK

Posted by

Silas

at

11:46 AM

![]()

Labels: Bimmo 325 E30

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment